Last Updated on March 3, 2025

To lubricate your Lippert slide-out, start by cleaning the slide-out mechanism to remove dirt and debris. Focus on key points like the internal mechanisms behind the wipe seal, nylon blocks for Schwintek systems, and slide-out arms.

Use recommended lubricants like CRC Power Lube with PTFE or 3-IN-ONE RVcare Slide-Out Silicone Lube for peak performance.

Remember to apply lubricants sparingly and frequently check for cleanliness to maintain functionality and safety. There’s more vital info on enhancing slide-out maintenance.

Key Takeaways

- Ensure the slide-out is clean before lubrication to prevent dirt accumulation that can cause wear and tear.

- Use recommended lubricants like CRC Power Lube with PTFE or 3-IN-ONE RVcare Slide-Out Silicone Lube on key components.

- Focus on lubrication points such as the internal mechanisms behind the wipe seal and the nylon blocks in Schwintek systems.

- Apply lubricant sparingly to avoid attracting dirt and inspect for any unusual noises or signs of wear during maintenance.

- Follow manufacturer guidelines and perform regular visual inspections while cleaning to maintain optimal performance of the slide-out system.

Prep Your Slide-Out: Understanding Lippert Slide-Out Systems

Understanding Lippert slide-out systems is vital for maintaining your RV’s functionality. Lippert offers both electric and hydraulic slide-out systems, each with unique features. The Schwintek system employs gears and racks mounted on the slide-out walls, driven by electric motors, while the Through Frame system uses a gear and rack setup beneath the floor, utilizing an electric cylinder and motor.

Key components include electric motors, gears, racks, rollers, rails, and control panels, all working together for smooth operation. Identifying your slide-out system is essential for effective maintenance; look for motor locations and drive mechanisms.

Regular cleaning and occasional lubrication are recommended to guarantee peak performance and longevity of your slide-out system. Additionally, utilizing a cable driven slide out system allows for larger, heavier slide outs, enhancing your RV’s living space.

Importance of Lubrication for Slide-Outs

While maintaining your RV’s slide-out system, it’s vital to recognize the importance of lubrication. Proper lubrication prevents wear and tear by reducing friction between moving parts, which can save you from costly repairs.

Additionally, it minimizes noise, ensuring your slide-outs operate quietly and smoothly. By lubricating regularly, you enhance the overall functionality, making it easier to open and close the slide-outs.

Lubricants also protect against corrosion, acting as rust inhibitors for metal components, thereby extending their lifespan. Regular maintenance not only reduces future repair costs but also improves reliability, enhances user safety, and helps maintain your RV’s value.

Ultimately, lubrication is fundamental for a well-functioning slide-out system, ensuring efficient and safe operation. Regular treatment of rubber sealing gaskets is also essential for maintaining the integrity of your slide-out system.

Recommended Lubricants for Maintenance

When maintaining your Lippert slide-out, selecting the right lubricant is essential for peak performance. You should prioritize lubricants that are compatible with the materials used in your slide-out, as well as those that protect against rust and corrosion.

Regular maintenance is crucial to prevent issues, such as synchronization problems, which can affect the functionality of your slide. Always refer to the manufacturer’s recommendations to guarantee you’re using the most effective products for your specific model.

Ideal Lubricant Types

Selecting the right lubricant is crucial for maintaining your Lippert slide-out system’s performance and longevity. Here are some ideal lubricant types to contemplate:

| Lubricant | Key Features |

|---|---|

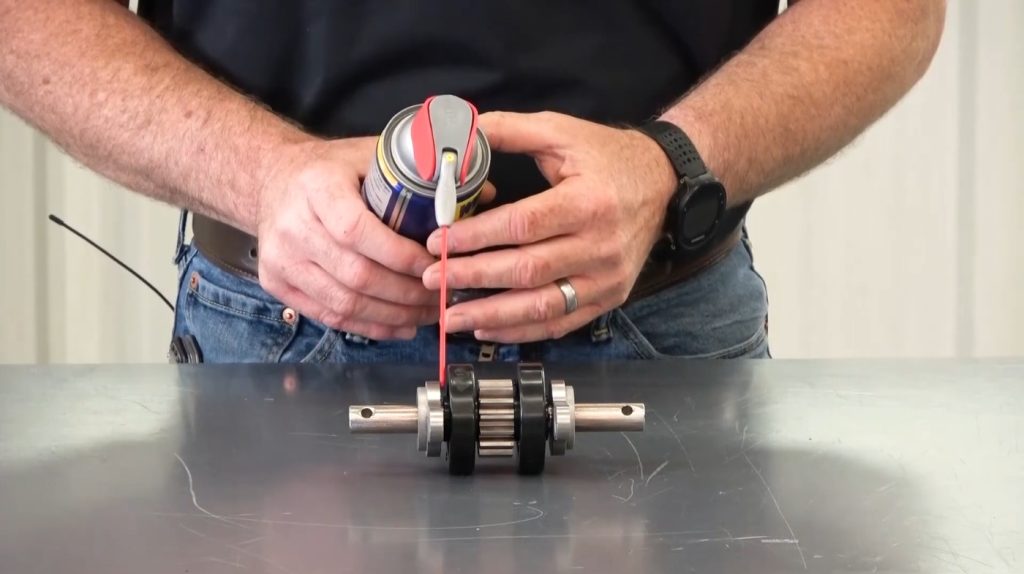

| CRC Power Lube with PTFE | Reduces squeaks in Schwintek systems |

| 3-IN-ONE RVcare Slide-Out Silicone Lube | Quick-drying, safe for multiple materials |

| Hot Shot’s Secret RV Slide-Out Lubricant | Protects against rust and corrosion |

Dry lubricants are recommended for mechanical parts to prevent dirt accumulation, while seal conditioners maintain seals. Always verify that the lubricant is compatible with the materials in your slide-out system to avoid damage.

Regular checks and precise application can enhance the effectiveness of your lubrication efforts.

Manufacturer Recommendations Importance

Understanding manufacturer recommendations for maintaining your Lippert slide-out system is essential to guarantee peak performance and longevity. Lippert explicitly advises against lubrication, emphasizing cleanliness instead. Lubricants can attract dust and dirt, leading to increased wear and potential system failure.

Following the guidelines in your Lippert manual guarantees the slide-out operates as intended. Regularly checking the slide-out motor maintenance can help prevent operational issues and ensure smooth functionality.

Regular cleaning prevents rust, protects seals, and contributes to smoother operation. While some users may report improved performance with lubrication, this practice isn’t universally endorsed and can complicate maintenance.

Adhering to manufacturer recommendations simplifies upkeep, extends component lifespan, and mitigates risks associated with improper maintenance. Always prioritize cleanliness over lubrication for best results.

Key Lubrication Points to Focus On

To guarantee peak performance of your Lippert slide out, focus on key lubrication points that directly impact its functionality. Prioritize the internal mechanisms, especially behind the wipe seal on the transmission driveshaft and the nylon blocks in Schwintek systems.

Additionally, you can connect with others facing similar RV problems in the community for more tips and support. Avoid lubricating outer visible tracks and instead use a bent tube to reach internal areas.

| Area | Recommended Lubricant |

|---|---|

| Internal mechanisms | CRC Power Lube with PTFE |

| Sliding surfaces | Blaster Dry Lube with Teflon |

| General use | Dry lubricants like silicone/graphite |

Frequency of Lubrication Maintenance

Regularly maintaining the lubrication of your Lippert slide out is essential for ideal performance and longevity. It’s generally recommended to lubricate at least twice a year, ideally before and after the camping season.

However, if you’re in harsh environments like coastal areas with salty air or high dust levels, you may need to lubricate more frequently. Your slide-out’s usage also impacts lubrication frequency, more usage means more lubrication.

While Lippert doesn’t provide specific guidance for all models, adopting a preventative approach helps avoid costly repairs. Always consider environmental conditions, slide-out type, and lubricant choices to determine the best maintenance schedule tailored to your RV’s needs.

Regular cleaning and lubrication will also help identify when additional lubrication is necessary.

Additional Maintenance Tips for Longevity

Maintaining your Lippert slide-out goes beyond lubrication; it involves a thorough approach to ascertain longevity and peak performance.

First, keep your slide-outs closed when not in use, which protects components from the elements. Regularly inspect and clean the seals with mild soap and water, applying dry lube protectants to reduce friction.

Additionally, ensuring a quiet operation of mechanical components can enhance overall comfort during use. Pay attention to mechanical components; verify rollers and rails are lubricated and check for wear. Perform visual inspections for any signs of damage and monitor for unusual noises during operation.

Additionally, engaging with the RV community can provide valuable insights and tips for maintaining your slide-out. Clear debris from the slide-out roof to prevent blockages. Finally, don’t hesitate to seek professional assistance for complex repairs, assuring your system remains in top condition.

Manual Operation in Emergencies

When the electronic system of your Lippert slide-out fails or the slide gets stuck, knowing how to manually operate it can save the day.

First, identify your slide type—Schwintek or rack & pinion—as the manual operation methods differ. Verify your RV is on a level surface and the battery is fully charged. For Schwintek slides, locate the control box, press the reset button six times, then hold it on the seventh to engage manual mode. Use the regular switch to move the slide.

For rack and pinion, disconnect the battery to avoid backfeed, then use the crank tool to turn clockwise until the slide is flush. Always consult your owner’s manual for specific instructions. Remember that electronic manual override can be a helpful procedure to gain control when standard operations fail.

When to Seek Professional Help

If you’re facing complex mechanical issues, like uneven movement or unusual noises from the slide-out motor, it’s essential to seek professional help.

Regularly performing routine checks can help identify problems before they escalate. Electrical system failures, such as blown fuses or unresponsive controls.

Persistent operational problems, especially those beyond basic lubrication, shouldn’t be ignored to prevent further damage.

Complex Mechanical Issues

Complex mechanical issues in Lippert slide-outs can arise unexpectedly, often signaling the need for professional intervention. If you encounter frame damage, such as bent structures, don’t attempt to fix it yourself; this can jeopardize safety and stability.

Gear system failures are intricate and typically require specialized tools and expertise, making professional repair crucial. RV slide outs operate using electric motors or hydraulics to extend and retract, and any malfunction in these systems should be addressed promptly.

Likewise, if your hydraulic system exhibits issues with actuators, it’s best to seek help from a qualified technician. Additionally, motor replacement is usually beyond DIY capabilities, necessitating professional assistance.

Finally, if you’re facing extensive repairs or a complete system overhaul, don’t hesitate to consult an expert to guarantee your slide-out operates smoothly and safely.

Electrical System Failures

Electrical system failures in Lippert slide-outs can lead to significant operational issues, so recognizing the signs early is essential. If you experience frequent breaker tripping or persistent power loss despite resetting breakers or replacing fuses, it’s time to seek professional help.

A burning smell or electrical fires require immediate attention and should never be ignored. Understand that RV batteries provide power for slide-outs when off-grid, so ensure they are functioning properly. Complex electrical repairs, especially involving wiring or circuit modifications, are best left to experts.

Additionally, if you’re unsure about safety concerns, consult a professional to avoid potential hazards. Don’t risk your safety or the functionality of your slide-out; addressing electrical issues promptly can prevent more severe problems down the line.

Persistent Operational Problems

While you might notice occasional operational issues with your Lippert slide-out, persistent problems need immediate attention. If you experience these symptoms, it’s time to seek professional help:

- Mechanical Problems: The slide-out doesn’t move or moves slowly despite clearing obstructions.

- Hydraulic Issues: You notice fluid leaks or the system fails to hold its position.

- Misalignment: The slide-out extends unevenly or drifts out of position, indicating installation or wear issues. This can often be attributed to gear and rail slipping during operation.

- Environmental Effects: Contamination from road salt or ice leads to unpredictable performance.

Ignoring these signs can result in more significant damage and costly repairs. Act swiftly to maintain the functionality of your slide-out and guarantee a safe, enjoyable experience.

Frequently Asked Questions

Can I Use Regular Oil for Lubrication?

Using regular oil for lubrication is like trying to fix a leaky roof with a bucket—it’s not going to solve the problem. Regular oil attracts dirt and can stain surfaces, making it unsuitable for your needs. Instead, opt for silicone-based lubricants that dry quickly and repel contaminants.

They reduce friction effectively without the mess. Always prioritize the right lubricant to maintain your equipment’s performance and longevity, ensuring a smoother operation.

How Do I Know if My Slide-Out Needs Lubrication?

To determine if your slide-out needs lubrication, listen for squeaky noises or feel increased friction during operation. Inspect for visible signs like cracks or drag marks on components, indicating wear. Regular maintenance checks help identify lubrication needs, especially if you notice these symptoms.

Different slide types have varying lubrication requirements, so understanding your specific system’s needs is essential in maintaining peak performance. Always keep an eye on the condition of seals and moving parts.

Are There Specific Brands of Lubricants to Avoid?

When selecting lubricants, you should avoid white foamy products, sticky lubricants, and lithium-based greases that leave residue. These can cause motor issues and attract dirt.

Additionally, steer clear of unspecified brands that lack manufacturer recommendations. Always prioritize using products specifically approved for your equipment to guarantee smooth operation and longevity of your slide-out system.

What Tools Do I Need for Lubrication?

To properly lubricate, you’ll need several tools. Start with a suitable lubricant, like silicone spray or dry moly. Have a straw or tube handy for precise application.

Gather cleaning supplies to clear debris before you begin. A screwdriver’s essential for removing panels and accessing hidden tracks.

Don’t forget protective gloves to keep your skin safe. Finally, a flashlight will help you inspect dark areas effectively.

Can I Lubricate My Slide-Out in Winter?

Winter can be a slippery slope for your slide-out maintenance. You can lubricate your slide-out, but it’s essential to be cautious.

Low temperatures can thicken lubricants, potentially hindering performance. If you decide to proceed, make sure you use a silicone-based lubricant to combat moisture.

Before application, check for ice buildup or obstructions that could cause damage. Always test the operation afterward to confirm smooth movement and prevent future issues in frosty conditions.

Extend Your Slide-Out’s Lifespan with Proper Lubrication

In summary, regular lubrication of your Lippert slide-out is vital for peak performance and longevity. Did you know that well-maintained slide-outs can extend their lifespan by up to 50%? By focusing on key lubrication points and using the right products, you can prevent costly repairs and guarantee seamless operation.

Don’t overlook this essential maintenance task—keeping your slide-out in top shape not only enhances functionality but also improves your overall RV experience.